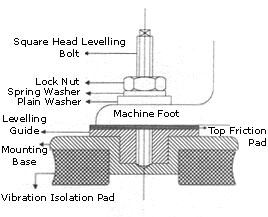

To obtain optimum performance from machine tools after installation, the noise levels must be reduced and the external and inherent vibrations kept to a minimum. In order to achieve this, Avmount Anti-Vibration mountings can be used that are not only easy to install but also provide for precise-levelling. The mounts absorb shocks and impacts caused by punching machines and presses as also the horizontal forces from injection moulding machines and shaping machines.

The mounts keep the machinery firmly in position whilst aiding smooth operation. Avmounts eliminate mass movements of shaping machines and prevent them from drifting. Lathes, grinding machines and other precision machines are protected from external shock loads and vibrations.

| Avmount Machine Mounts | AV-02 | AV-04 | AV-08 | AV-12 | AV-20 |

| Diameter | 50 mm | 80 mm | 120 mm | 160 mm | 200 mm |

| Height Including Guide | 33 mm | 43 mm | 48 mm | 57 mm | 65 mm |

| Adjustable Level | 33-37 mm | 43-55 mm | 48-60 mm | 57-70 mm | 65-77 mm |

| Loading/Mount Machine tools | 150 kg | 300 kg | 500 kg | 800 kg | 1500 kg |

| Loading/Mount-Grinding Machine | 200 kg | 400 kg | 800 kg | 1200 kg | 2000 kg |

| Loading/Mount-Power Presses | |||||

| Max: Strokes/Min: 200 | 40 kg | 120 kg | 250 kg | 500 kg | 800 kg |

| 160 | 60 kg | 140 kg | 300 kg | 600 kg | 1200 kg |

| 125 or Less | 100 kg | 200 kg | 400 kg | 1000 kg | 1500 kg |

| Adjustable Screw | M10 X 1.5 X 100 | M12 X 1.25 X 100 | M12 X 1.25 X 125 | M12 X 1.25 X150 | M16 X 1.5X150 |

| M16 X 1.5X100 | M16 X 1.5X125 | M16 X 1.5X150 | M20 X 1.5X150 | ||

| M20 X 1.5X125 | M20 X 1.5X150 | M24 X 2X150 |

| AV-02 | AV-04 |

| 33-37 mm | 43-55 mm |

| AV-08 | AV-12 |

| 48-60 mm | 57-70 mm |

| AV-20 | |

| 65-77 mm |