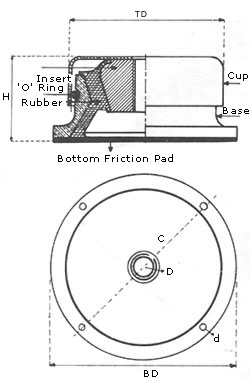

Avmount Vibro Dampers are designed to use the isolating media, rubber in this case, both in compression and in shear. It is bonded to metal during vulcanisation such that the design makes the mounting have an equal stiffness in all directions. The mounting can be used for mobile applications also, since the base of the mounting is provided with holes for attachment to the chassis. It also has a friction pad bonded to the bottom of the base for proper fixation of the machine to the floor in case of stationary applications. Hence no bolting is necessary under these conditions.

Avmount Vibro Dampers are highly efficient yet economical vibration and shock isolators. This product is EXCLUSIVELY manufactured by us. You can use them for vibration of compressors, diesel generators, fans and motors as well as for the protection of mounted equipment from external vibration or shock. Being of extremely robust design, these isolators are particularly suitable for rugged conditions and give trouble-free and continued service. Their life is generally equal to that of the machinery or plant which is mounted on them.

Avmount Vibro Dampers Type AVM in addition to isolating machinery and structures from vibration and shock, provide a means sitting stabilisation so that the floor areas are undisturbed with no need for bolting or grouting in. machinery is left free-standing and thus can be re-sitted with ease. To meet certain requirements, however, holes are provided in the base plate.

Machinery mounted on our dampers is isolated both actively and passively. The machinery is isolated actively in the sense that the machine which is a source of vibration is so isolated that the incidence of transmission of vibration to the floor upon which it rests is reduced to an extent, and passively in the sense that the machine which would be affected adversely by external sources of vibration is now insulated from them.

Avmount Vibro Dampers Type AVM have a bottom friction pad bounded to the bottom of the mounting and hence there is no necessity of adding another friction pad.

| TD | BD | Free H | D | PCD'C' | Diameter'd' | |

| Type AVM 60/120 | 58 mm | 80 | 40.5 | M10 | 65 | 7 mm |

| Type AVM 75/180 | 78 mm | 115 | 50.5 | M12 | 95 | 9 mm |

| Type AVM 225/375 | 100 mm | 150 | 59.5 | M16 | 120 | 11 mm |

| Type AVM 300/800 | 125 mm | 185 | 72.5 | M20 | 150 | 13 mm |

| Type | Shore

Hardness |

F |

d |

Fn |

%

Isolation at fd |

||

1000

rpm |

1500

rpm |

||||||

| AVM 60/120 A

|

45 |

60

kg |

4.4

mm |

8.6

Hz |

60 |

87 |

|

| AVM 60/120 B | 55 |

90 kg |

4.1 mm |

8.9 Hz |

60 |

85 |

|

| AVM 60/120 C | 65 |

120 kg |

4.3 mm |

8.7 Hz |

60 |

85 |

|

| AVM 60/120 D | 75 |

150 kg |

4.3 mm |

8.8 Hz |

60 |

85 |

|

| AVM 75/180 A | 45 |

75

kg |

5.8

mm |

7.5

Hz |

73 |

88 |

|

| AVM 75/180 B | 55 |

120 kg |

5.8 mm |

7.5 Hz |

73 |

88 |

|

| AVM 75/180 C | 65 |

180 kg |

5.9 mm |

7.4 Hz |

74 |

89 |

|

| AVM 75/180 D | 75 |

225 kg |

5.8 mm |

7.5 Hz |

74 |

89 |

|

| AVM 225/375 A | 45 |

225

kg |

5.9

mm |

7.4

Hz |

74 |

89 |

|

| AVM 225/375 B | 55 |

275 kg |

6.0 mm |

7.3 Hz |

75 |

90 |

|

| AVM 225/375 C | 65 |

375 kg |

6.2 mm |

7.2 Hz |

76 |

91 |

|

| AVM 225/375 D | 75 |

450 kg |

6.0 mm |

7.2 Hz |

76 |

91 |

|

| AVM 300/800 A | 45 |

300

kg |

5.8

mm |

7.5

Hz |

73 |

88 |

|

| AVM 300/800 B | 55 |

500 kg |

6.3 mm |

7.1 Hz |

77 |

92 |

|

| AVM 300/800 C | 65 |

800 kg |

5.3 mm |

7.8 Hz |

70 |

87 |

|

| AVM 300/800 D | 75 |

1000 kg |

5.3 mm |

7.8 Hz |

70 |

87 |

|

Note: It is essential that all mounts deflect equally so that the system has a single natural frequency and not different natural frequencies at each point.

Installation of equipments on VIBRO DAMPERS is the modern method of installing equipment which must be protected from shock and vibrations which are inherent in many environments.

In mobile applications the equipments remains steady and isolated from the base vibrations during transit.